-40%

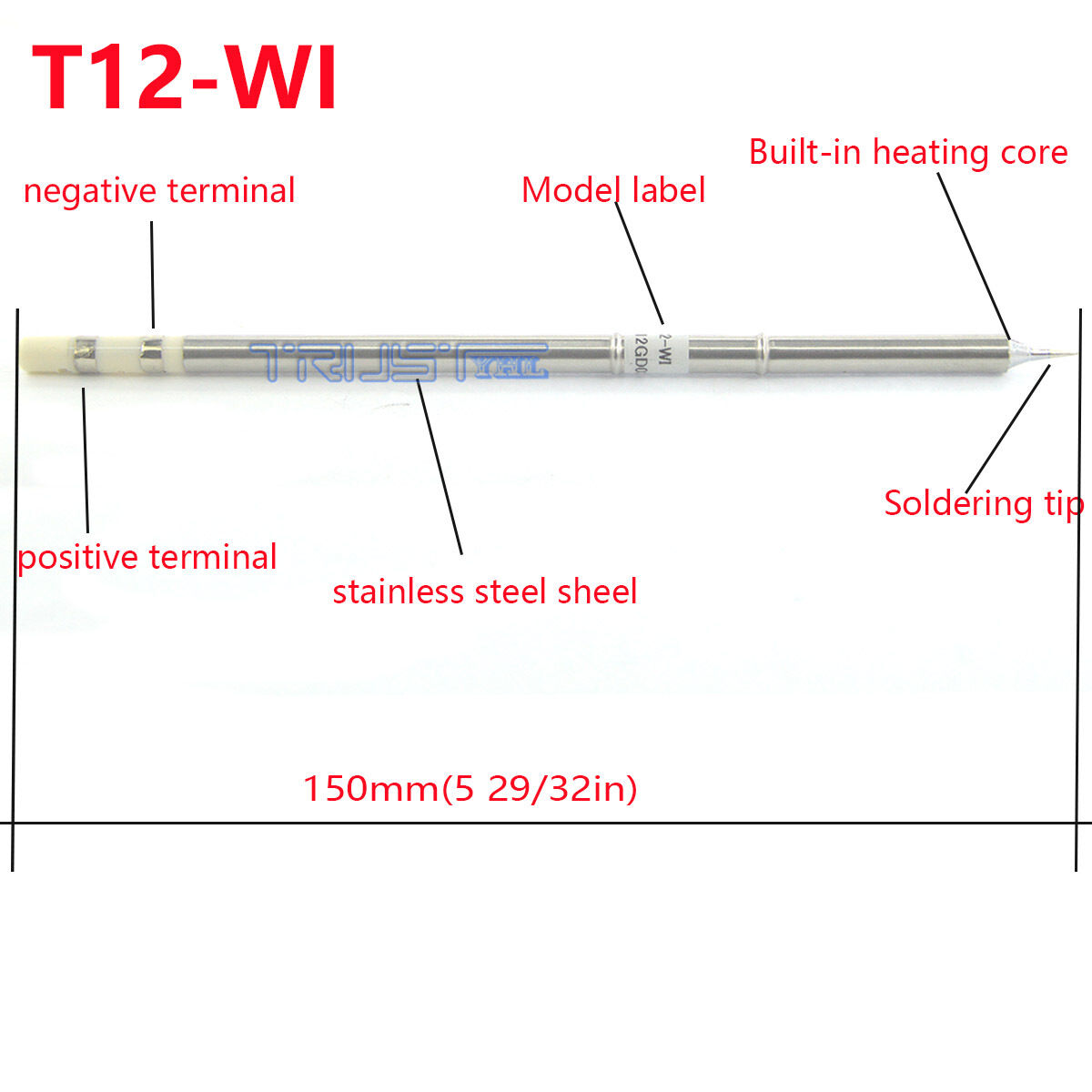

For Hakko Shape-WI PCB T12-WI Replace Soldering Solder Iron Station Tip New

$ 4.11

- Description

- Size Guide

Description

For Hakko Shape-WI PCB T12-WI Replace Soldering Solder Iron Station Tip NewFeatures:

Raw materials are made of oxygen - free copper.

The appearance of the use of special machinery and technology production, size and

precision.

Using the latest plating process to ensure that the special corrosion-resistant alloy

layer thickness of 1MM, welding life of more than 50,000 points.

Scope of application -

White FX-950 / FX- 951 / HAKKO942 and so on

Weight: 0.3oz

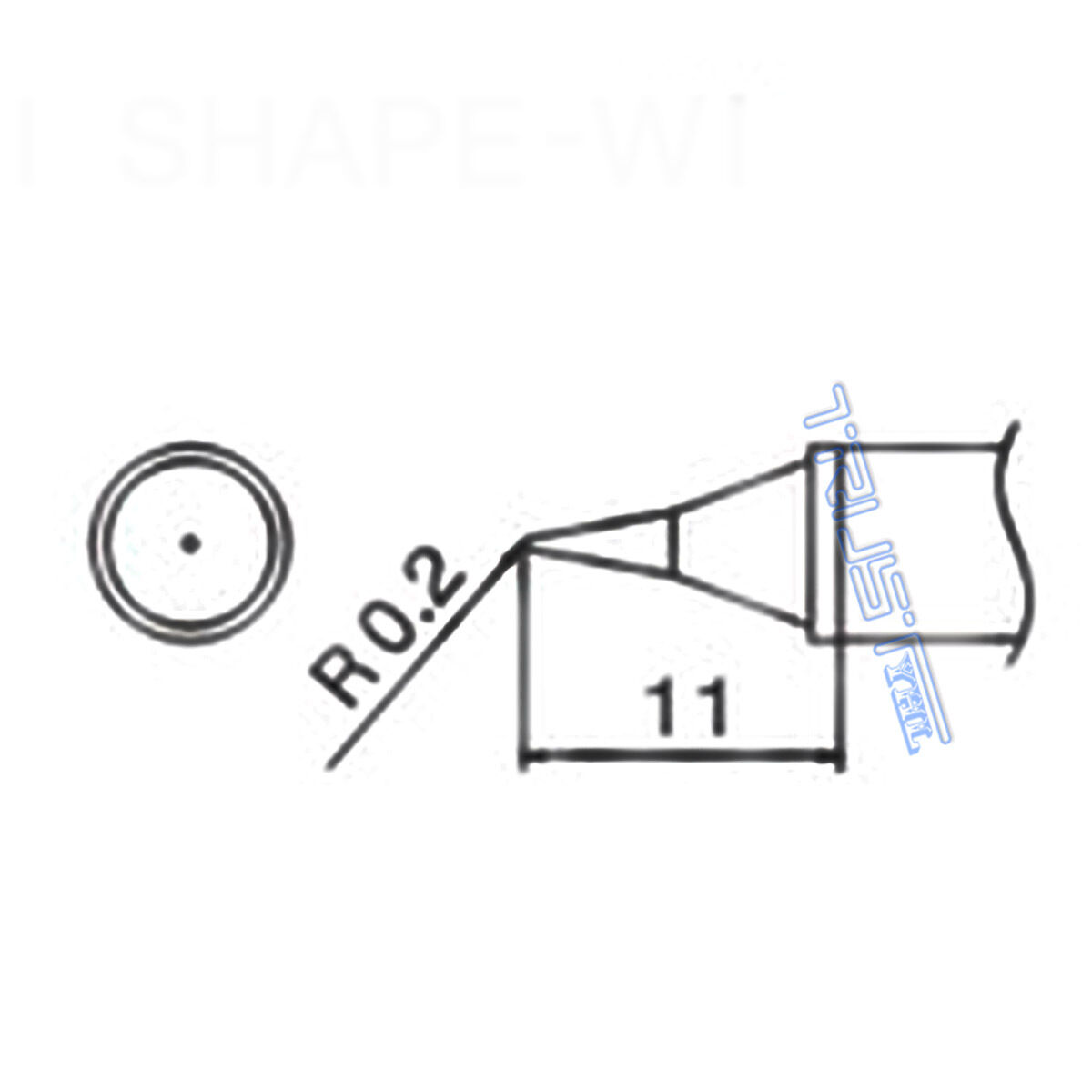

Type I:

Features: tip tip fine.

Application: suitable for fine welding, or welding space is small, you can also modify

the solder chip produced when the tin bridge.

Type B (conical)

Features: B-type iron head without direction, the tip of the tip can be welded.

Application: suitable for general welding, regardless of the size of the solder joints,

but also the use of B-type tip

D type (one word approved Tsui)

Features: welding part of the approved part.

Application: suitable for the need for more than the amount of welding, such as welding area, thick

terminals, welding pad welding environment.

Type C (beveled cylindrical)

Features: with the tip of the tip of the welding part of the welding, suitable for the need for more

than the amount of welding.

Applications:

C-type tip application range and D-type soldering head similar to, such as welding area, thick

terminals, the case of large pad.

0.5C, 1C, 1.5CF and other soldering iron is very fine, suitable for welding small components, or

modified surface welding generated when the tin bridge, tin and so on. If the welding only a small

amount of solder, then use only in the slope of tin-type CF-type iron head is more suitable.

2C, 3C-type tip, suitable for welding resistors, diodes and the like components, large pitch SOP and

QFP can also be used.

4C, suitable for large terminals, ground on the circuit board. Power supply parts such as the need

for greater heat welding occasions.

K type

Features: The use of blade-shaped part of the welding, vertical or pull welding can be welded, are

multi-purpose tip.

Application: Applicable to SOJ, PLCC, SOP, QFP, power supply, grounding part of the components,

modified tin bridge, connectors and other welding.

The main material produced by the tip

The iron head is mainly composed of copper and iron nickel chrome tin 5 kinds of metal materials.

Copper ----- as a thermal conductor is the main component of the iron tip, accounting for about 85%

of the tip of the material. Copper thermal conductivity is good. Help the tip of the rapid heating.

High-quality tip with T2 oxygen-free copper / copper. Copper content of 99.99%. Excellent thermal

conductivity. General tip with T1 copper / oxygen-free copper. Copper content of 97.5%. Thermal

effect is also good. But many businesses use brass. In order to reduce costs. The same is also

reduced iron Head heat effect.

Iron ------ from the role of corrosion resistance is the key factor in the life of the tip of the

iron. Good iron iron plating process is a small current for a long time plating, making the iron

layer crystal structure fine and dense. Corrosion resistance Well, such a long iron long life.Te tin

effect is good. Galvanized technology in general business mainly use high current rapid plating. By

plating the end of the service life. Usually there will be iron-plated layer thick tip heat transfer

is not good The most critical technology is how to control the precision of the iron layer, the

thickness and the thickness of the deviation.

Nickel ------ play the role of iron-plated layer rust-proof, and easy to chrome behind

Chrome ------ do not stick tin to prevent the use of tin to the tip of the body to run. High-quality

iron tail chrome time in more than 5 minutes. Ordinary decorative chrome in about a minute

The role of chromium;

1. To improve the hardness of the welding nozzle. Wear resistance. Temperature and corrosion

resistance and so on

2. anti-climbing tin.

3. beautiful decoration.

Tin in the head. Use the sticky tin parts.

The basic principle of iron tip selection

1. The shorter the tip of the soldering iron tip, the shorter the heat conduction capacity is

2. The thicker the better the tip of the soldering iron, the greater the heat capacity of the

soldering iron, the smaller the temperature change during the welding process

3. Do not use the tip. Do not use the tip. Tip class soldering iron thin. Thermal area of small

welding generally need to set the high temperature life is less than the head of the horseshoe head

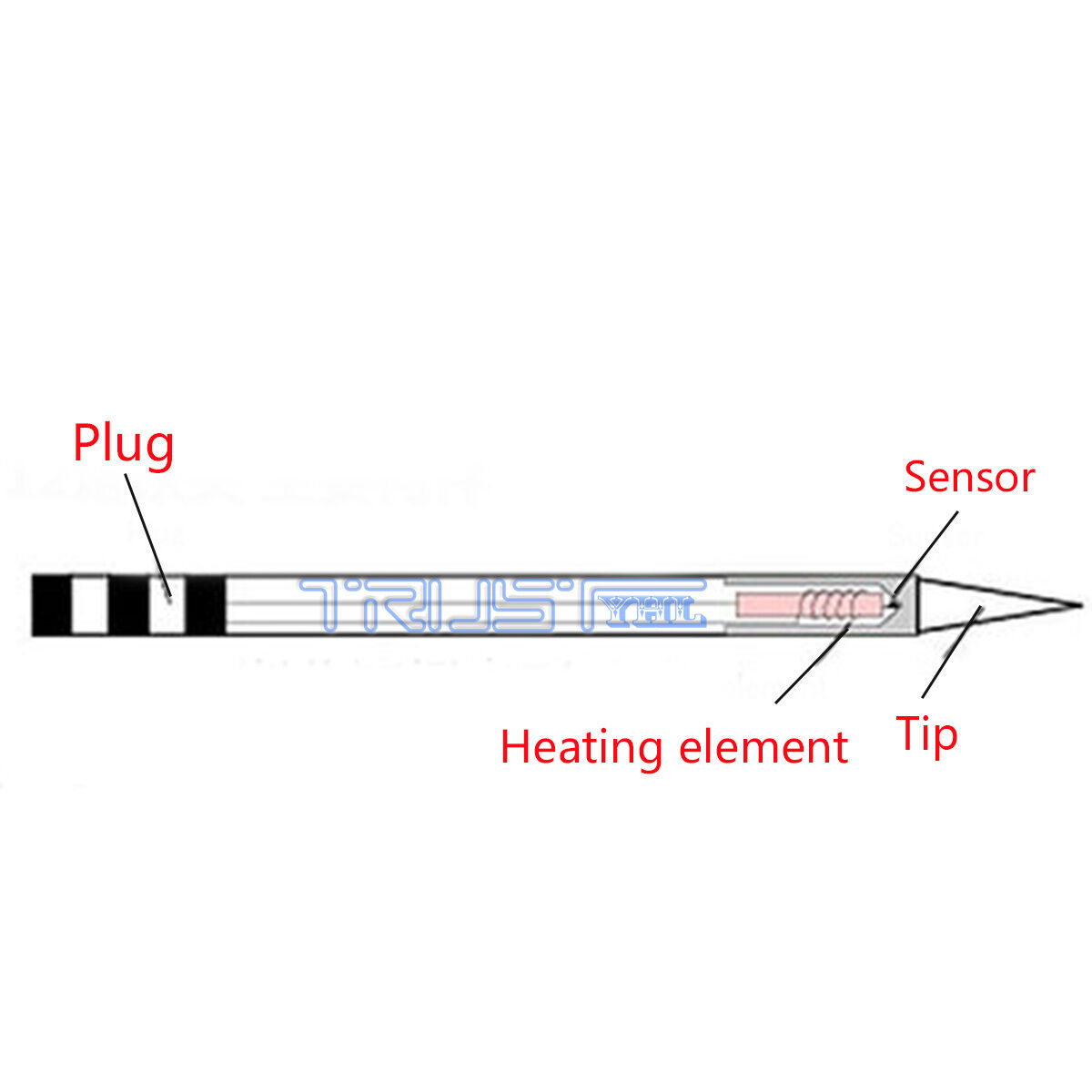

T12 tip use precautions

Just buy the tip of the iron why show the temperature bounce To

Because the new T12 tip inside the heating core did not go through the high temperature, so the

initial use will be a little temperature jump. Generally do not need special treatment. Natural use

1-2 days after basically not bounce. If you need immediate effect. The temperature is adjusted to

380 ℃ while heating to the tip of the tin on the tip of the tin. After burning four or five minutes

after the turn to be cooled and then re-boot (1 times can not be repea)

Soldering Tip(T12-WI) x1